- Messages

- 1,785

- Reaction score

- 2,240

- Points

- 312

- Location

- 27574

- Boat Make

- Yamaha

- Year

- 2009

- Boat Model

- X

- Boat Length

- 21

hopefully not beating this subject to death......I had a thread on the subject "elsewhere" so may be a repeat. Figured I'd start one here as well.

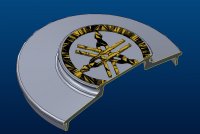

We have a pretty decent ABS plastic 3d printer at work. This past weekend I was starting some packing for the Bimini 2014 trip and to my horror I could not find the cover to my 12volt Blender .....

I brought the blender into work today. took a few measurements...added a little bling....and BOOM new cover !!

I have about 2.3 hours left on a total of 8+ hours of printing....after its bath in the morning I'll post up a few finished pics.....it's printing in a white material..black may be better...

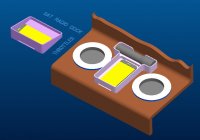

In the past I've made a few phone/flashlight trays for the boat in the free space around the throttles.

The crown Jewell I'm going to work on in the weeks to come are custom knobs to replace the rubber ones that bolt up the wake tower...I'm thinking if I make a "bowl" design, cradle a bolt in it, then pot it solid with a epoxy or similar material.....some fancy inlay/boat name or something on the handle face......stay tuned !!

We have a pretty decent ABS plastic 3d printer at work. This past weekend I was starting some packing for the Bimini 2014 trip and to my horror I could not find the cover to my 12volt Blender .....

I brought the blender into work today. took a few measurements...added a little bling....and BOOM new cover !!

I have about 2.3 hours left on a total of 8+ hours of printing....after its bath in the morning I'll post up a few finished pics.....it's printing in a white material..black may be better...

In the past I've made a few phone/flashlight trays for the boat in the free space around the throttles.

The crown Jewell I'm going to work on in the weeks to come are custom knobs to replace the rubber ones that bolt up the wake tower...I'm thinking if I make a "bowl" design, cradle a bolt in it, then pot it solid with a epoxy or similar material.....some fancy inlay/boat name or something on the handle face......stay tuned !!