ScarabMike

Jetboaters Admiral

- Messages

- 2,223

- Reaction score

- 2,061

- Points

- 302

- Location

- Green Cove Springs, FL

- Boat Make

- Yamaha

- Year

- 2022

- Boat Model

- AR

- Boat Length

- 19

While washing the Scarab this weekend, I noticed and repaired a couple of locations of rust that everyone with a Scarab should look at. Ill have pictures soon on how I fixed them, but if not taken care of soon, they will grow to bigger issues.

1. Under the passenger, and driver seat there is a black handle that controls the forward and reverse adjustments. This handle looks like it is made of regular steel, and isnt treated. Mine were rusted from the aluminum base to the plastic handle. If not caught, they could have simply rusted off, and I would have lost the ability to adjust the seats. Now, the seat base, and lateral (side to side) was aluminum, and very sturdy. Im thinking this was an oversight.

2. Trailer built in guide bunks rusting around the connecting screw to the carpeted bunks. It looks like the trailer itself is galvanized and sprayed with Gatorhyde. But, these guide bunks dont look like they are galvanized, just coated steel.

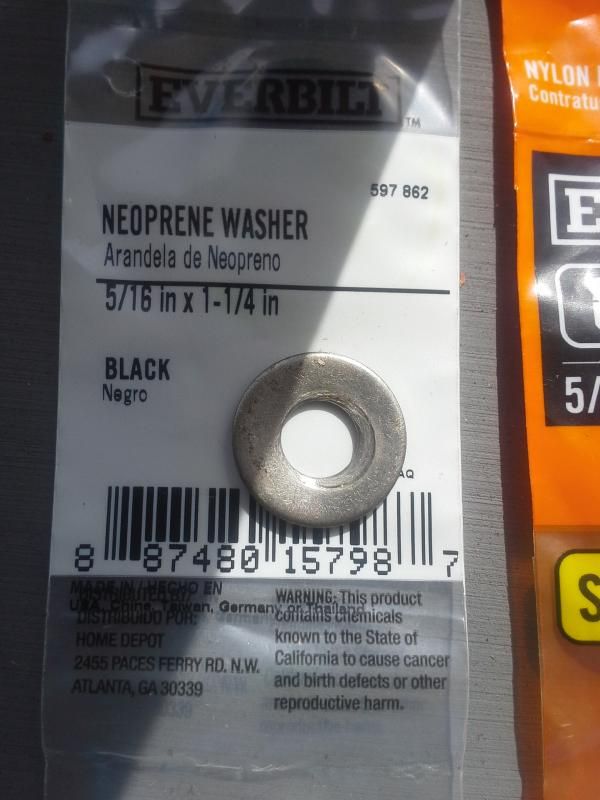

I had to grind the rust off these locations, and coat them with galvanizing spray, prime, and coat with Rustolium paint. Ill keep everyone up to date in this thread on how effective my repair will hold up.

1. Under the passenger, and driver seat there is a black handle that controls the forward and reverse adjustments. This handle looks like it is made of regular steel, and isnt treated. Mine were rusted from the aluminum base to the plastic handle. If not caught, they could have simply rusted off, and I would have lost the ability to adjust the seats. Now, the seat base, and lateral (side to side) was aluminum, and very sturdy. Im thinking this was an oversight.

2. Trailer built in guide bunks rusting around the connecting screw to the carpeted bunks. It looks like the trailer itself is galvanized and sprayed with Gatorhyde. But, these guide bunks dont look like they are galvanized, just coated steel.

I had to grind the rust off these locations, and coat them with galvanizing spray, prime, and coat with Rustolium paint. Ill keep everyone up to date in this thread on how effective my repair will hold up.