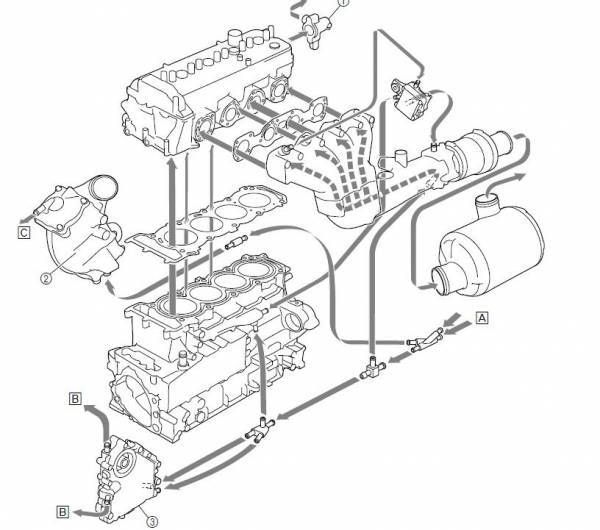

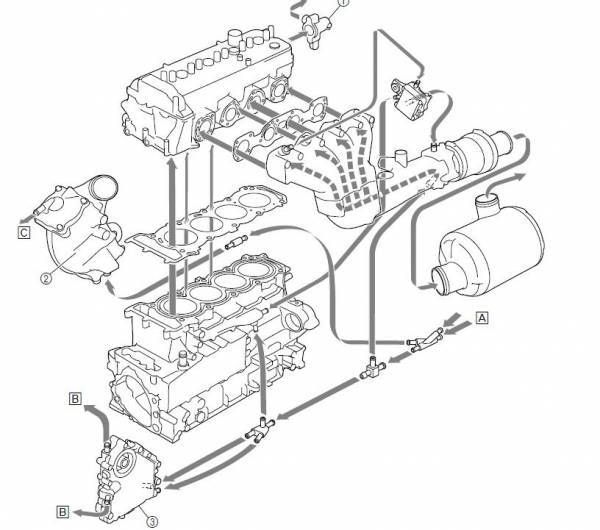

doing a little more research, here is the cooling water flow, this is for a 192 with a intercooler (I believe is [HASH=132]#2)[/HASH] but other than that it should be the same for yours,

I'm confused because you can see the water input at the bottom of the exhaust sleeve and it appears to take some water

a. into the exhaust manifold and then into the engine

b. passes it through sleeve to the exit fitting on top of the sleeve to the

is the box in the red circle going to the exhaust system to exit via the water box or is it flowing towards the motor ?

I can't find that box on the parts schematic to give it a proper name.

View attachment 131041